- Mon to Sat 9:00am to 6:00pm

- +91 9560-9978-48

- anil@crimsonoilfieldservices.com

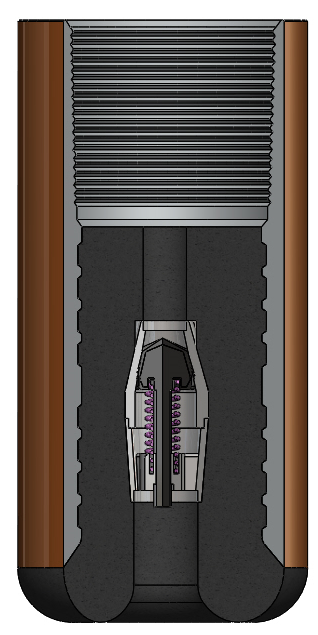

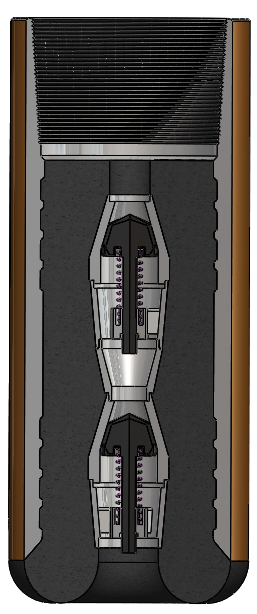

Non Rotating Float Collar ( Single/Double Valve )

The Non-rotating Float Collar is attached to the end of the casing string and they are used to stop slurry from flowing back. Material inside is easily drillable; the anti-rotation mechanism on the top improves drill-out performance. The valve consists of rubber and polymer materials with high tensile strength. Single or double valves are available.

These are available in 2 7/8" to 30 "sizes + any special size on customer demand

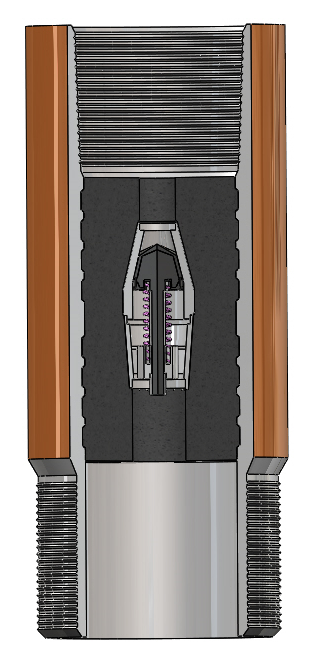

Guide Shoe

COS's Guide Shoe comes with a simple and economical means to run casing in the well bore. All the internal components are fully PDC drillable. This design contains an internal taper on the bottom to ensure trouble-free entry of drilling tools back into the casing string after drill out and during drilling operation. All Guide Shoes and internal components are fully PDC drillable.

It reduces problems associated with hitting rock ledges therefore reducing chances of sidewell cave-in. These are available with Butt-welded, slip on and threaded end and from sizes 2 7/8” to 30” sizes + any special size on customer demand

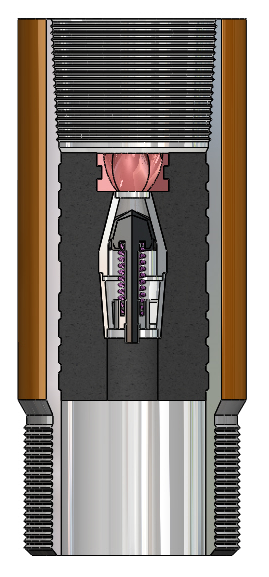

Conventional Float Shoe ( Single/Double Valve )

COS Float shoe supplied with plunger valve in most of the application. This design ensure positive sealing in vertical, horizontal and deviational wells. Material used for float equipment is seamless casing grade steel. Float equipment can be supplied in all grades of steel like K-55, L-80, N-80, C-95, T-95, and P110. COS's Float equipment are tested and rated in compliance with API requires specs.

The material used in the valves is High polymer plastic and valve is consisting of Natural rubber coated on phenolic substance. This non metallic valve encased and held in place with the high pressure cement mixture. The design and manufacturing process of valve allow for maximum circulation rates.

These are available in 2 7/8" to 30 "sizes + any special size on customer demand.