- Mon to Sat 9:00am to 6:00pm

- +91 9560-9978-48

- anil@crimsonoilfieldservices.com

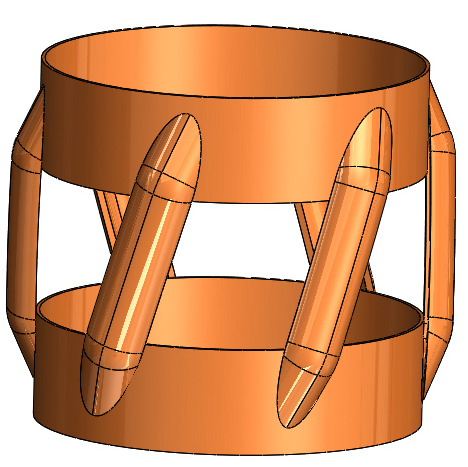

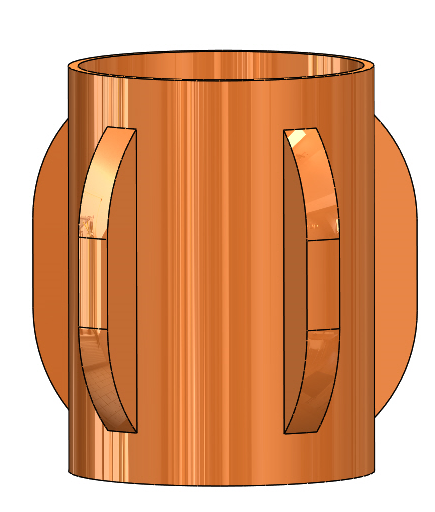

Zinc Straight Blade Solid Rigid Centralizer

COS's Zinc Straight Blade solid rigid centralizer provide the right feature for getting a good primary cementing job with maximum wellbore standoff with suitable functional. These centralizers provide ultimate drag and torque reduction with maximum fluid by pass.

These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.

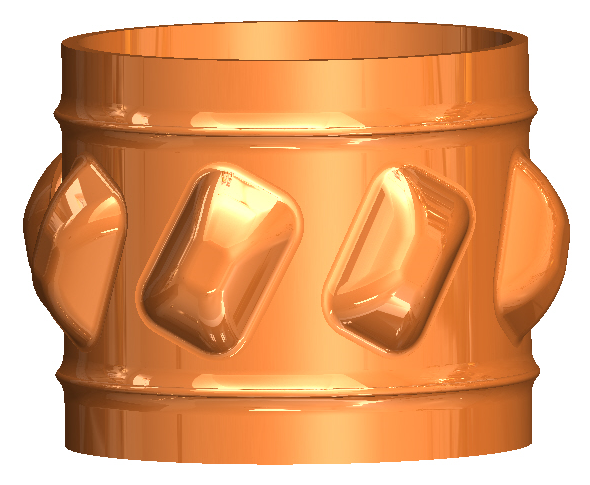

Roller Centralizer Low Torque Type

COS's Low Torque Roller Centralizers are specially designed to run in inclined or horizontal section. The rollers' envelope outside diameter is kept slightly larger than the centralizer fins' envelope outer diameter. The Rollers' envelope inside diameter is kept slightly larger than the fins' envelope inner diameter. When casing equipped with Roller Centralizer runs into the deviated or horizontal hole, the sliding friction between the casing and the borehole is converted into rolling friction.

In case of irregular hole diameter, the borehole wall has an impact force on the spiral centralizer during running casings, the use of rollers reduce this impact. Torque reduction is provided by vertical alignment of rollers on the periphery of Roller Centralizer.

These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.

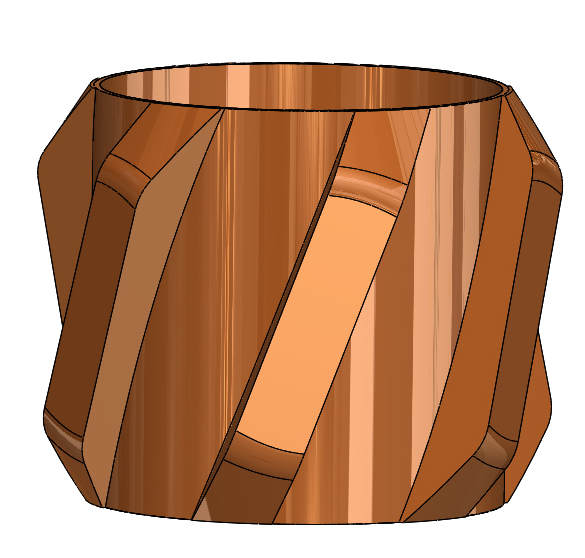

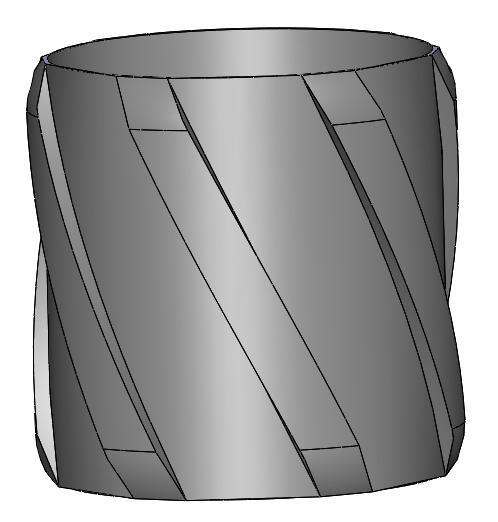

Aluminium Spiral Blade Solid Rigid Centralizer

COS's Aluminium Spiral Vane Solid Rigid Centralizers are developed in response to the need for better cementing in high deviated and horizontal well. These are designed to provide optimum flow and its fins or blades overlap the entire 360-degree open hole circumference. Therefore its reduced flow area between the spiral provides and creates vortex motion to increase fluid velocity with direction. Even without rotation, the relived angle fins/ blades induce turbulent flow for improved cutting and filter cake removal.

The angle of the uniquely designed spiral fin produced maximum fluid swirl, thus maximum removal of debris around the casing in any type of hole. These Centralizers withstand high well bore temperature while providing maximum horizontal standoff.

These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.

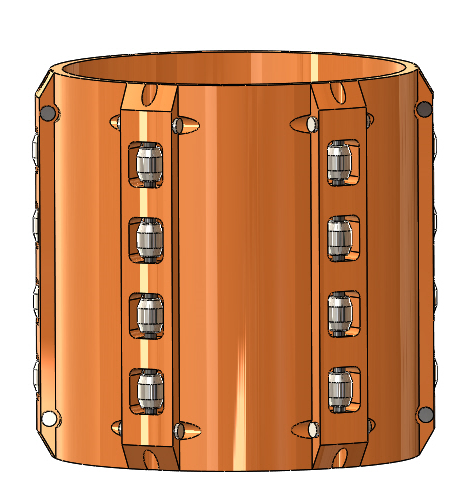

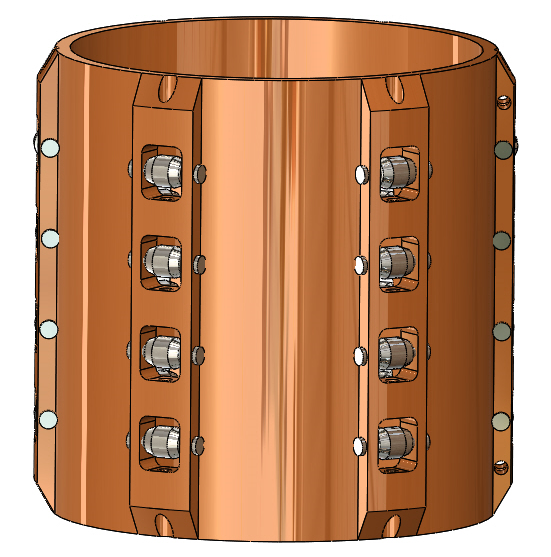

Slip On Welded Heavy Duty Positive Spirolizer

COS's Solid Heavy duty Spirolizer are specially designed for extra heavy load in highly deviated Horizontal well and for use with Liner Hangers. The heavy steel construction is highly effective as compare to other alloy. Wide symmetrical Spiral fins are welded to the one piece rolled formed Sleeve under required temperature and condition with extra low Hydrogen coated Electrodes, which assures ultimate strength and uniformity in every weld.

Steel construction provides superior toughness over other materials. Vanes can be selected to meet any hole dia from a choice of seven boat profile depths. Slip On Spirolizer are provided for direct installation on the pipe by slipping on and can be provided with compatible Stop Collars beveled from one side positioned by set screw. Hydrodynamic shapes of spiral fins allow optimal mud displacement and minimal pressure drop across centralizer. Induced vortex flows enable superior mud removal. They have high wear resistance and resist high side load. Slip On Solid Spiralizor are provided for direct installation on the pipe by slipping on and can be provided with compatible Stop Collars beveled from one side positioned by set screw.

These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.

Zinc Spiral Blade Solid Rigid Centralizer

COS's Zinc Spiral Vane Solid Rigid Centralizer are designed in such a way that it provides efficient functionality. These are checked on a regular basis and that are used in different industrial applications. The offered zinc spiral vane solid rigid centralizers are simple and convenient, extensively used for rough and fine polishing of metallurgical specimens. This gentle flow from the body to the height of the vane will eliminate scraping, gouging or digging into the formation and consequently reduce balling between the vanes.

These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.

Slip On Welded Positive Spirolizer

COS’s Spirolizer is designed specially for highly deviated or horizontal wells. Ideal for use with Liner Hangers. The steel construction ensures extra strength and superior toughness. The boat shaped Spiral fins minimize Drag Forces while running pipe. The fins glide smoothly in the low side of horizontal bore holes. Wide symmetrical fins are smoothly beveled on the both ends to have lower coefficient of friction and to ease casing movement in either direction.

Fins designs also resist high side load. Spirally oriented Fins are welded to the one piece rolled formed End Collar under required temperature and condition with extra low Hydrogen coated Electrodes, which assures ultimate strength and uniformity in every weld. Steel construction provides superior toughness over other materials.

Fins designs also resist high side load. Spirally oriented Fins are welded to the one piece rolled formed End Collar under required temperature and condition with extra low Hydrogen coated Electrodes, which assures ultimate strength and uniformity in every weld. Steel construction provides superior toughness over other materials.

These are available in 2 7/8" to 30 " sizes. Any special sizes or combination can be made available on request.